Industrial

Innovation

Process

"Let’s make innovation

drive your company"

Although innovation is essential for the development of industrial businesses, many companies either lack structured innovation processes or fail to utilize them effectively. To support these businesses, we offer a comprehensive, practical, and tailored approach for professional innovation management.

Why is industrial innovation so complex?

Managing industrial innovation comes with numerous challenges. Some are inherent to the manufacturing sector, such as industrial property, regulatory pressure, or the need for significant investments. Others stem from internal organizational factors, including a lack of focus in companies heavily oriented toward daily operations, difficulties in interdepartmental coordination, or challenges with open innovation. Is it possible to manage this complexity effectively? Yes, with the 5-40TM innovation process, it is.

What is the 5-40TM innovation process?

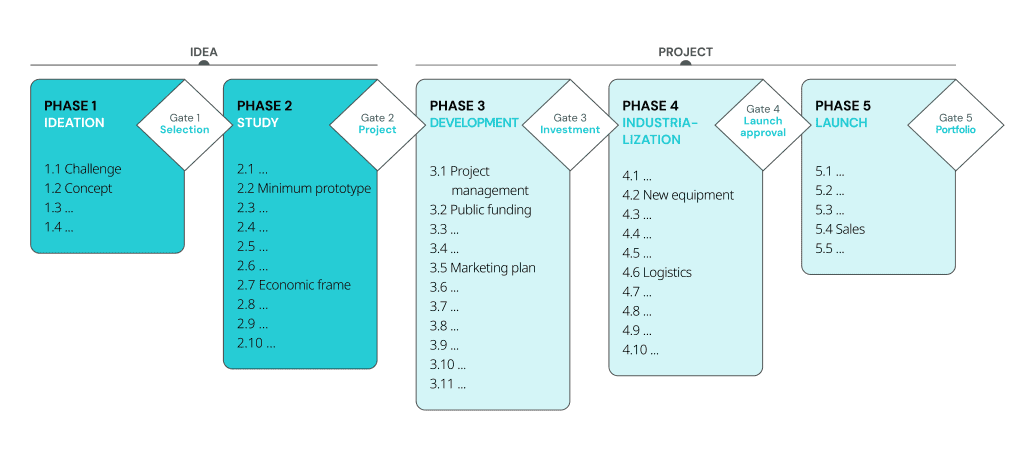

The 5-40TM innovation process is a method for managing industrial innovation that converts innovative ideas into new products, processes, or services launched in the market. It comprises 5 phases and 40 tasks, specifically designed to tackle industrial innovation challenges in an effective, efficient, rigorous, and agile manner. This is not a theoretical model, but a practical method developed and refined through real-world industrial innovation practices.

Which companies is it intended for?

The 5-40TM innovation process is primarily designed for industrial companies across sectors such as consumer goods, food, chemicals, materials, durable goods, components, etc. However, it can also be effectively applied to other industries.

Why choose the 5-40TM innovation process?

Because it enables the efficient management of all the company’s innovation. The process covers every stage, from idea generation to industrial and commercial development, and includes all types of innovation, such as open innovation. Innovation is consolidated into a single project portfolio or innovation pipeline, which helps organize and track its integration into the business.

Because it adapts to the company, regardless of its sector, objectives, or size. It is a flexible process, managed with simple governance and minimal organization: an Innovation Coordinator and an Innovation Committee. These features make it an ideal management method for companies of all types.

- Because it increases the efficiency of work teams. As a manual, the process outlines the necessary steps, resources, participants, and decisions to be made. It also anticipates the real organizational and material challenges that teams will face. It is a definitive roadmap for driving action.

What do we offer?

In-company training on the 5-40TM innovation process for employees involved in innovation-related tasks. In addition to acquiring specialized knowledge across various domains, participants will develop a thorough understanding of the entire process and how it integrates into the business. This will nurture a culture of collaboration and drive innovation. The training includes a copy of the book *Industrial Innovation Process 5-40TM*, where participants can find additional details and examples to guide their day-to-day application.

- Implementation of the process within the company. It includes tailored planning based on the company’s context, a project portfolio tool, the selection and coaching of the Innovation Coordinator, and the creation and support of the Innovation Committee. The recommended implementation period is up to six months.

Program Director

Arturo L. Casado Domínguez

An expert in industrial innovation and its integration into business management systems, he is also the author of the book Industrial Innovation Process 5-40TM. With over 25 years of experience in RDI management within international industrial groups, the last 15 years have been spent as the Director of RDI for the Insulation Division of the ETEX Group. Prior to that, he held various RDI leadership roles at Procter & Gamble in the Fabric and Home Care division in Brussels, including the establishment of the first joint open-innovation technical center between Procter & Gamble and BASF in Ludwigshafen.

With extensive knowledge of the industrial consumer goods, chemical, and materials sectors, he is the inventor of 36 international patents and has introduced numerous innovative technologies and products to the market. He holds a Ph.D. in Chemistry from the University of Valladolid, was a Research Fellow at the Massachusetts Institute of Technology (MIT), and more recently participated in the Business Innovation Program at Deusto Business School.

Request Information

Contact